Full-Protective Double Exchange Platform laser cutting machine

Full-Protective Double Exchange Platform laser cutting machine1000W-12000W.

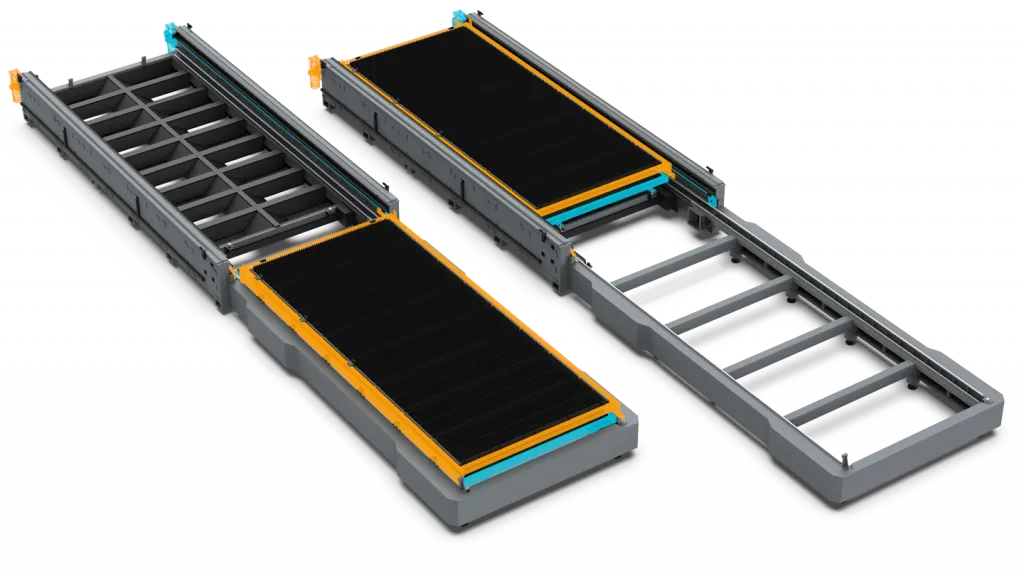

The 4th generation GLDMA fiber laser cutter is mainly designed for high power from 2kw to 20kw. With full-protection cover, it can protect the worker from the harm of laser rediation and reduce the environment pollution. It’s also equipped with auto-exchangeable platforms, which can save the loading time and improve the processing efficiency. It only takes he exchange platform 20 seconds to complete the exchange.

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery Various working size optional

Auto Oil-filling

Intelligent system for auto oil filling oil cut-off avoided

Cost-Effective

Low waste of raw materisals Low investment with short payoff period

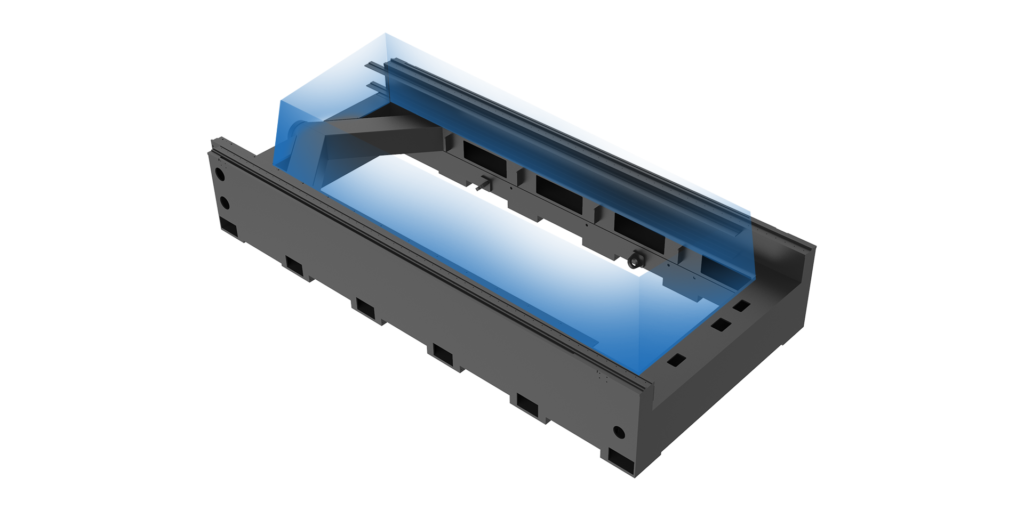

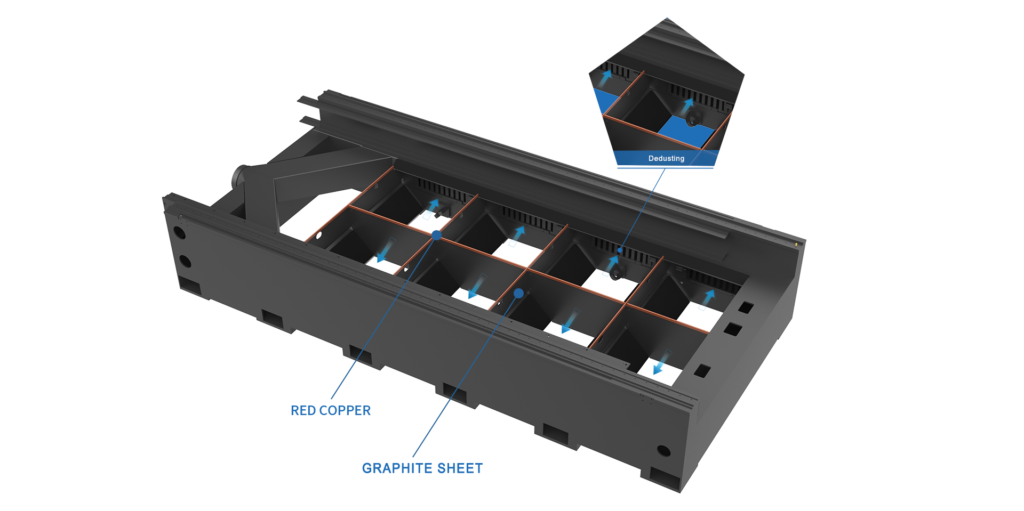

Heavy-load Thermal Isolated Hollow Bed

The heavy-load thermal isolated hollow bed is welded with high-quality steel plates and pipes. After welding, stress relief annealing, secondary aging treatment, and precise processing by ultra-large gantry milling machine ensure that the bed has sufficient structural stability and shock resistance.

The bed will not be deformed after long-term use, which improves the service life of the equipment.

Intelligent Spiral Vacuum Dust Removal

The Fifth-generation Aviation Aluminum Alloy Beam

Intelligent Control System

Auto focusing laser head

Lightning swap

What is this Machine Used for?

Parameter of Laser Cutting Machine for Steel

| Model | RAS-3015/RAS-4015/RAS-4020/RAS-6015/RAS-6020 metal laser cutting machine |

| Working Area | 3050*1525/4050*1525/4050*2020/6050*1525/6050*2020 |

| Laser Power(kw) | 1/1.5/2/3/4 |

| Maximum Speed(m/min) | 80 |

| Maximum acceleration(g) | 0.8 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |