Discover how GLDMA Shearing Machine technology can help you optimize your production

More productive sheet metal machines, new customized solutions, and easy-to-use option suites are designed to meet the customer’s real needs.

Swing beam shears - Guillotine shears

GLDMA Shears have been manufactured since 1995 and have been installed and working in a wide variety of sheet metal cutting operations for many industries. Years of experience has helped us develop durable, low distortion and precise cutting machines.

Shears are machine tools used for straight cuts on sheet metal. On a swing beam shear the swing beam moves with the upper blade in a circular arc. On a guiottine shear the upper beam moves straight down.

QC12K SWING BEAM GUILOTINE SHEAR

QC12K Series Shears today, tomorrow and forever with you.

High technology standards, design and user-friendly interface QC12K provides perfection with high standard safety, efficient solutions that strengthen your skills and add value to your company. We have reduced the cutting angle to achieve straight precision and minimum twist tolerance.

QC11K GUILLOTINE SHEARS WITH REDUCER

World standards equipped QC11K Series shears high-tech products offer you exact solutions.

GLDMA QC11K Series products provide a reliable, effective and economical solution. Knowledge, ability and experience has been the basis for the development of our mechanical and electronic drive components. Product performance and quality is never compromised while manufacturing QC11K Series.

Hydraulic Guillotine Shears VS Swing Beam Shearing Machine

Gate-type shearing machine

Gate-type shearing machine uses frame structure with all steel welding.It has four angle, eight sides with a right-angle guide rail, high precision, good rigidity, and the use of hydraulic pre- tightening. The whole hydraulic system adopts two-way cartridge integrated valve,and can be configured with stroke digital display, photoelectric protection device and mobile table (convenient to change the mold). The gate-type shearing machine has a double function of both the upper slider and the lower hydraulic pad, the working pressure stroke can be adjusted in the specified range according to the process requirements, it is easy to operate with the centralized control button.

Function features:

- Use the whole welding frame structure and vibration aging treatment. The machine has good rigidity, high precision and good precision retention.

- Use three-point supporting axle rolling guide rail. The upper tool rest roll gaplessly in the rolling guide rail. Rotating the hand wheel can adjust the service life of the blade.

- The movable blade support and four-eged long blade are provided for easy adjustment of blade gap uniformity, improve shear quality and prolong blade service life.

- Use tandem cylinder synchronization system. The machine is forced uniformly. By adjusting the flow of tandem cylinder,it is very convenient to adjust the shear angle, which can meet the needs of different shear plate thickness.

- Use motorized rear stopper device and electronic counter.It is convenient to adjust the position of rear stopper.

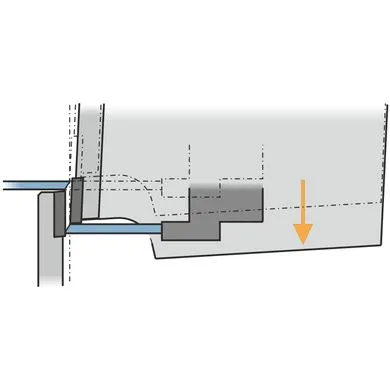

Swing-type shearing machine

Swing-type shearing machine usually adopts inclined blade shearing. It has been widely used because of its simple structure, low failure rate, high shearing efficiency and no distortion and warping after cutting. In the shearing process, as the tool rest does rotary movement, the angle and shearing gap of the swing-type shear will change.

The machine is all steel welding structure. Hydraulic transmission, vibration to eliminate stress, and it has high strength and good rigidity. Hydraulic swing-type shearing machine do downward shearing movement and nitrogen cylinder return by using the main cylinder (fixed on the wall panel). So simplified the hydraulic system operates more stably. The upper tool rest of the swing-type shearing machine swings around a fixed axis in the shearing process. Through leverage, the fulcrum has little force, which can improve the life of shearing blade and machine. The whole machine is in compact structure, and can electrodelessly adjust the stroke of the upper tool rest, which greatly improves the working efficiency.