WILA Smart Tooling

SMART TOOLING STARTS HERE!

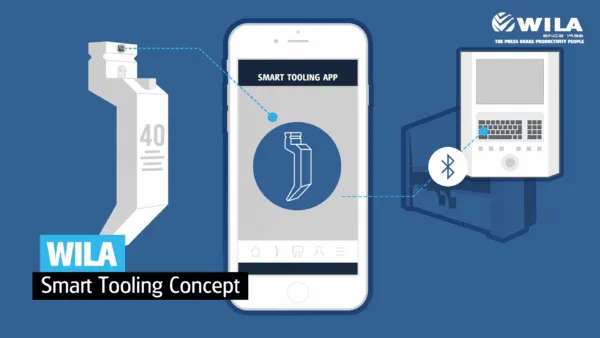

WILA introduces the Smart Tooling App (Android and iOS) for the tool management of press brake tooling.

The Smart Tooling App is part of the WILA Smart Tooling Concept: from easy and fast data entry to simplified inventory management and Bluetooth synchronization with the press brake control.

Grow Your Business With Wila

Smart Tooling App

WILA introduces a smartphone app which offers tool management for press brake tools. The Smart Tooling App allows WILA customers to experience the advantages of digitalization and data connectivity: access to tool data anytime, anywhere; major time savings; error-free tool data entry and simplified stock management.

All WILA New Standard Premium tools have a unique DM-code. With the WILA Smart Tooling App you can scan all tools at once, using the DM-code on the box or scan each tool separately. After scanning the DM-code you have immediate access to the tool’s specifications and the correct tool data files for your press brake control. Share this tool data directly to your cloud and add the tool files to your press brake control!

Smart Clamping System With Bluetooth

The Smart Tooling concept contains a lot more than just the Smart Tooling app. A Bluetooth module will be integrated in our TIPS* smart clamping systems. With this TIPS clamping system you can scan and add your TIPS system with the Smart Tooling app via the Bluetooth connection for full integration with your tool data. Afterwards you can synchronize the tool data in real time to your press brake control via the Bluetooth connection in the clamping system, saving valuable production time. The WILA Smart Tooling concept adopts a step by step approach to take press brake tool management to Industry 4.0 standard.

Take the first step by downloading the WILA Smart Tooling App!

Smart Tooling Concept

To further enrich the Smart Tooling Concept it will be expanded with additional features and functions. The built-in electronics in the clamping system and tooling will serve as a platform for data communication. This platform can be seen as an enabling platform for new applications that require a data infrastructure from tooling and clamping system towards the press brake. Big data analysis will help to further optimize the overall bending process in the future.

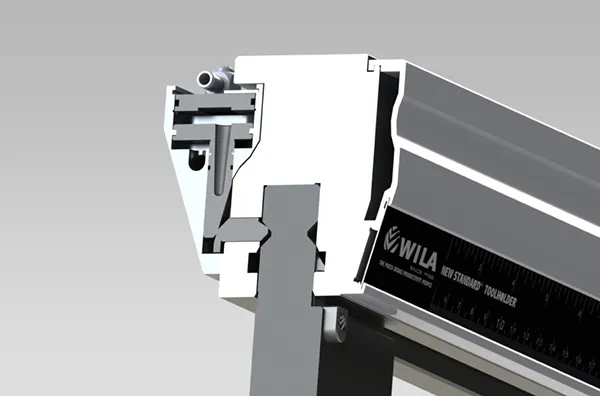

PNEUMATIC CLAMPING

Powerful Self-Locking® Performance

The tools are clamped with air pressure. The biggest advantage of our patented Self-Locking® mechanism is that the tools can be clamped and released extremely quickly. This unique system leads to a much faster tool change and increases your productivity in the long term.

HYDRAULIC CLAMPING

High efficiency for frequent and fast tool changes

Ideal for meeting the most demanding requirements. Perfect for robotic tool changes. A flexible hose along the entire length of the system is used to transfer oil pressure to the tooling via hardened clamping pins, providing maximum reliability. Once the clamping system has been activated, all tools are automatically positioned, centered and aligned.

MANUAL CLAMPING

An effective economical solution for less frequent tool changes

Clamping bolts are used to center tools in the required position. When changing tools less frequently, it will be sufficient to use a manual clamping system, whereby the bolts are tightened by hand.