BCI Suction Panel Bending Center

BCI Suction Panel Bending Center

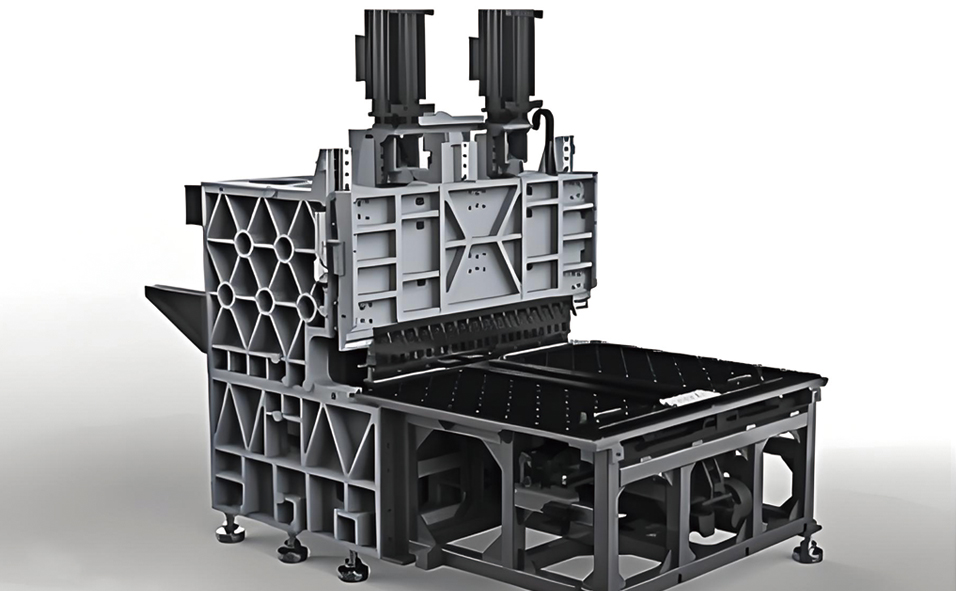

The flexible bending center focuses on solving various complicated sheet metal and bending problems in metal forming. Through multi-axis concurrent linkage, sheet metal operations are automatically completed, and the dependence on molds and labor is resolved from a technical perspective, which effectively improves production efficiency and reduces production costs.

Simple and solid press brake.

Work area can be customized and all types of tool clamping can be installed.

TAILORED-MADE PRESS BRAKE

Standard Equipment

- DELEM DA53T Controller

- Concurrent linkage of multiple axes

- Automatically complete the sheet metal work

- Increase production efficiency

- Reduce production cost

- Easily realize complex sheet metal bending requirements such as arc, stamped edge, return shape, closed shape, etc.

DELEM CNC Control System

N-PRESS

- The control system achieves simultaneous real nine-axis (15 axis) synchronization, ensuring stable bending motion and robust mechanical operation coordination.

Scientific Structural Design

- The core frame of the equipment is made of high grade QT500-7 and HT250 or above castings, which is stable and durable.

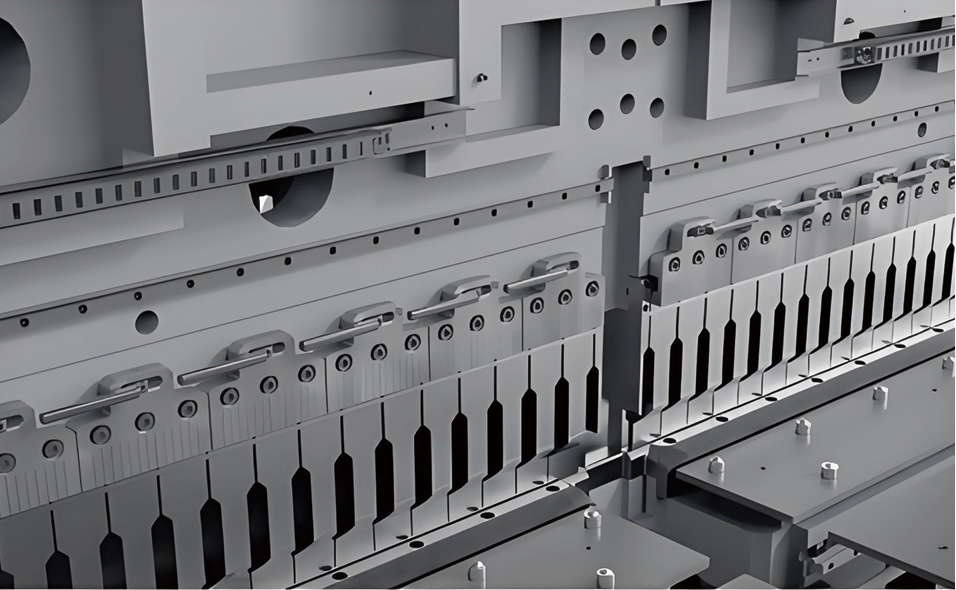

Precision Drive Mechanism

- The core movement mechanism of the whole machine adopts heavy-duty type grinding screw, the maximum screw reaches 8020, with heavy-duty type high-precision P3 roller type linear guide, the transmission rigidity is sufficient, high precision.

Quick-Release Tools

Advantage:

- Equipped with precision bending knife and press knife, the whole tool is hardened, the surface hardness is over HRC55,and it is easy to disassemble.

Precise Positioning System

- The loading adopts Y-axis and three-reliance positioning method, with suction cups to fix the workpiece, suitable for thin plate processing.