Bending Follower Supports

BEST WAY TO SUPPORT LARGE SHEETS FOR BENDING

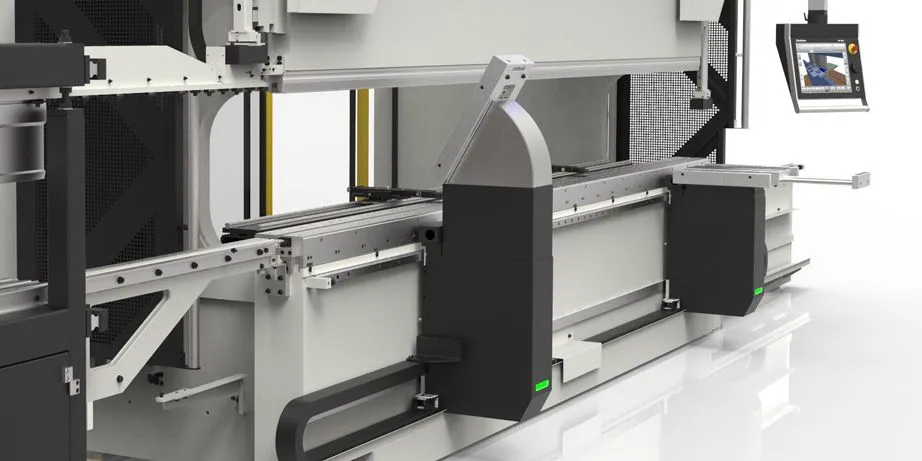

We are proud to introduce GLDMA new press brake electric sheet metal followers lifters, completely controlled by the CNC. For these reasons,GLDMA has created new motorised sheet followers to support the sheet during the bend. The dual interpolated axis configuration allows to continuously follow the part during the bend, to reduce the risk of scratches and counterbends and simplify machine operators’ work.

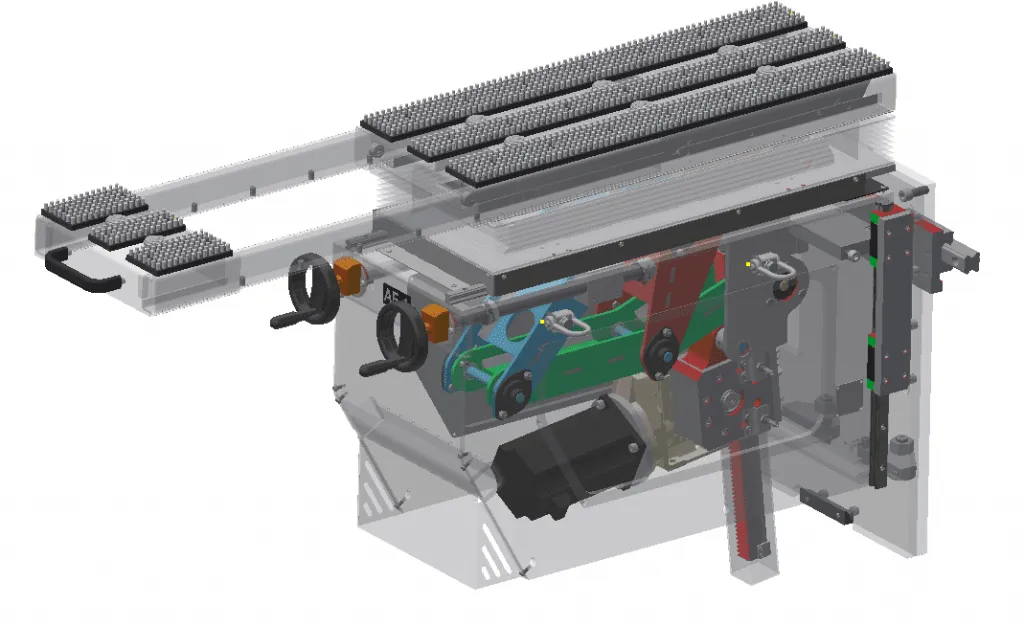

Front Sheet Follower Supports System

The hydraulic press brakes with Sheet supports follower system for bending long and thin sheets,It basically consists of a pair of sheet supports placed on the front of the machine at the height of the bending line (bottom tool). Supports are controlled by the CNC, following and supporting the sheet during the bending process.

- Automatic bending follower supports

- AP1 - AP2 CNC-controlled interpolated axes

- ecommended for heavy parts or large thin plate

- Bend as closed as 70°

- Load capacity – 180 kg per support

- Brush and support shaft dim 350x900 up to 1200 mm

Bending Follower Features

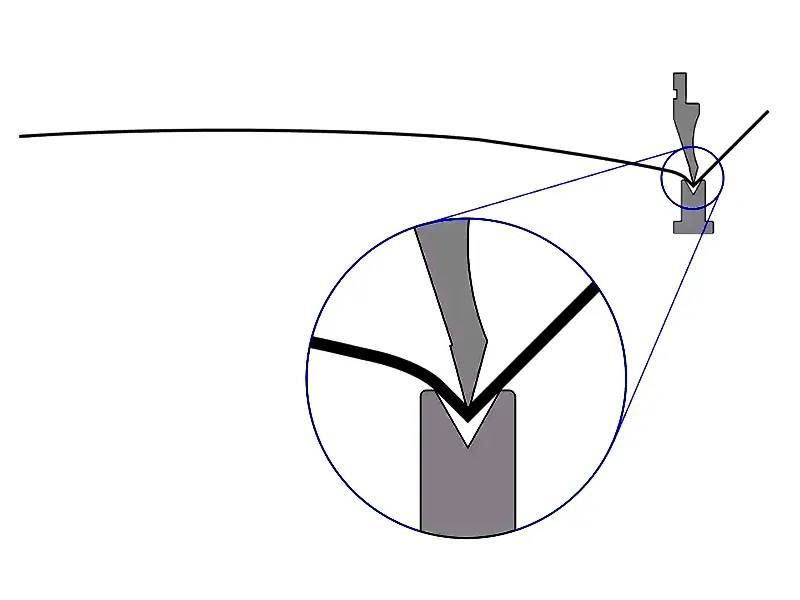

A counterbend occurs when we bend a very large, heavy and thin plate. The overhang generates a torque that makes the sheet bend around the die edge under its own weight, as we can see in the drawing. The sheet lifter helps to avoid this type of damage, supporting the plate during the entire bending cycle.

- AP1 - AP2 CNC-controlled interpolated axes

- Light solution, easy to move

- Adjustable according to the size of the workpiece

- Improved shop floor efficiency

- Improved shop floor efficiency

- Less physical strain and safety risks

- Protection from counterbends and scratches

- Bend as closed as 70°

- R axis -30/+170 mm; maximum die opening 100 to 160 mm

- Brush and support shaft dim. 350x900 mm extendable up to 1200 mm.

- Active or inactive modes that can be controlled directly on the sheet follower to avoid any safety risks (LED light located on the sheet follower).

Provide Valuable Practical Assistance

The latest followers for sheet metal bending aim to optimize the performances of our press brakes by reducing the time to set up the press brake and simplifying the work of operators.