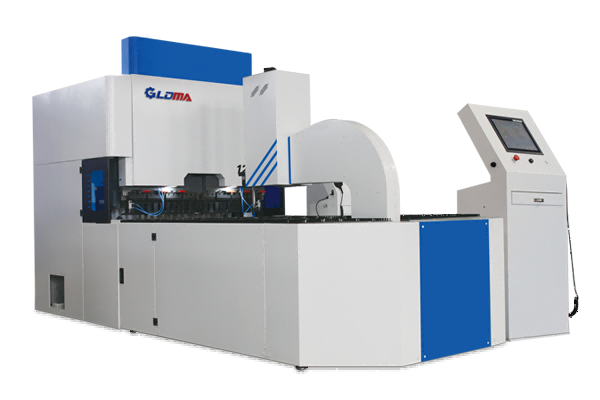

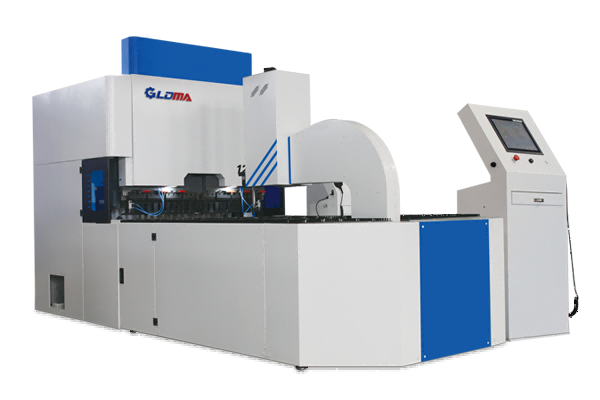

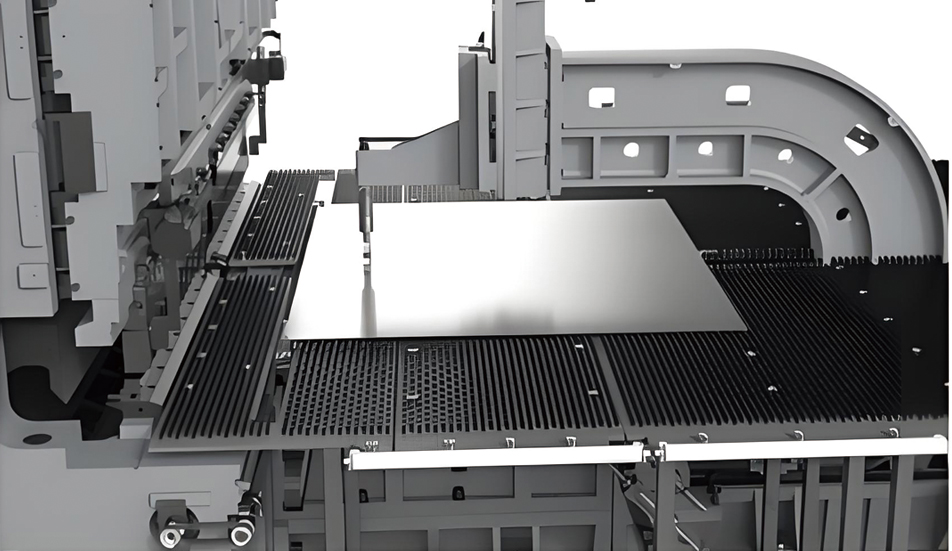

BSI Press Arm Bending Center

BSI Press Arm Bending Center

Suitable for a variety of bending material (carbon steel, 304 stainless steel, 201 stainless steel, aluminum plate, coated sheet, etc.)

Easy programming. Operator can customize the design and control of complex sheets according to their needs.

Full servo control, low energy consumption. Servo-based torque feedback system.

Simple and solid press brake.

Work area can be customized and all types of tool clamping can be installed.

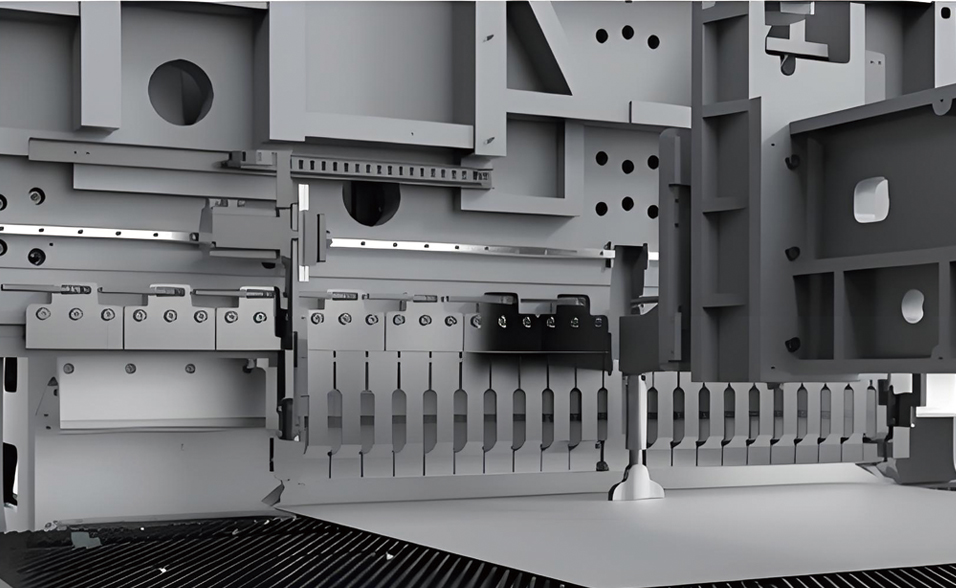

TAILORED-MADE PRESS BRAKE

Standard Equipment

- N-PRESS system

- Muliti-axis linkage control, with a high degree of automation.

- C-type pressure arm, lead screw multi-link transmission mechanism, pressure adjustment system.

- Three-axis fully automatic positioning system.Multiple positioning.

- Various feeding and discharging methods

DELEM CNC Control System

N-PRESS

- The control system achieves simultaneous real nine-axis (15 axis) synchronization, ensuring stable bending motion and robust mechanical operation coordination.

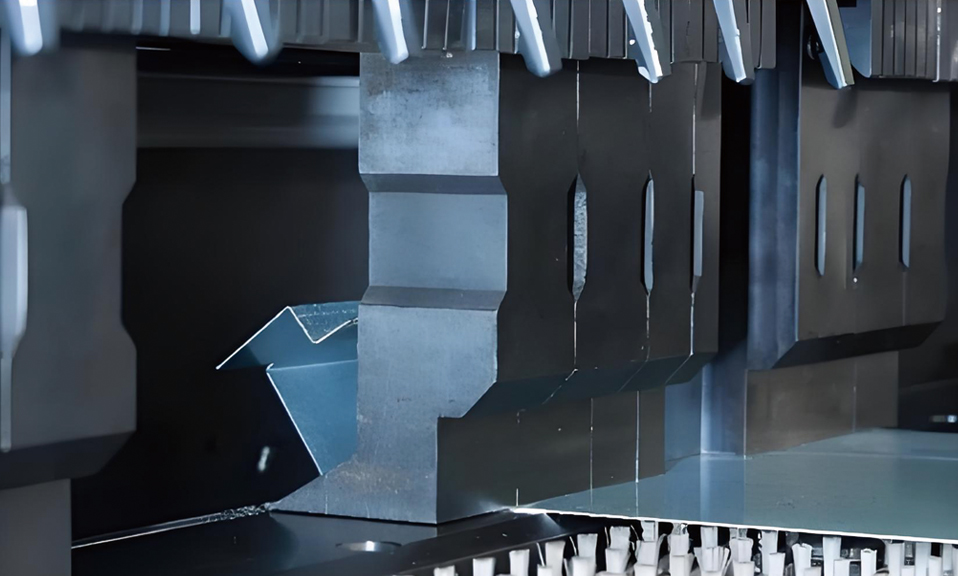

Power Hinge Knife (Optional)

- Effectively avoid interference and scratching by the workpiece surface.

Precision Drive Mechanism

- High-torque servo motor with pressure arm clamping workpiece, workpiece rotation adopts high-precision RV reducer, higher precision of rotation positioning. Shaped workpieces such as mesh hole, hollowing and thick plate are applicable, stable operation and high reliability.