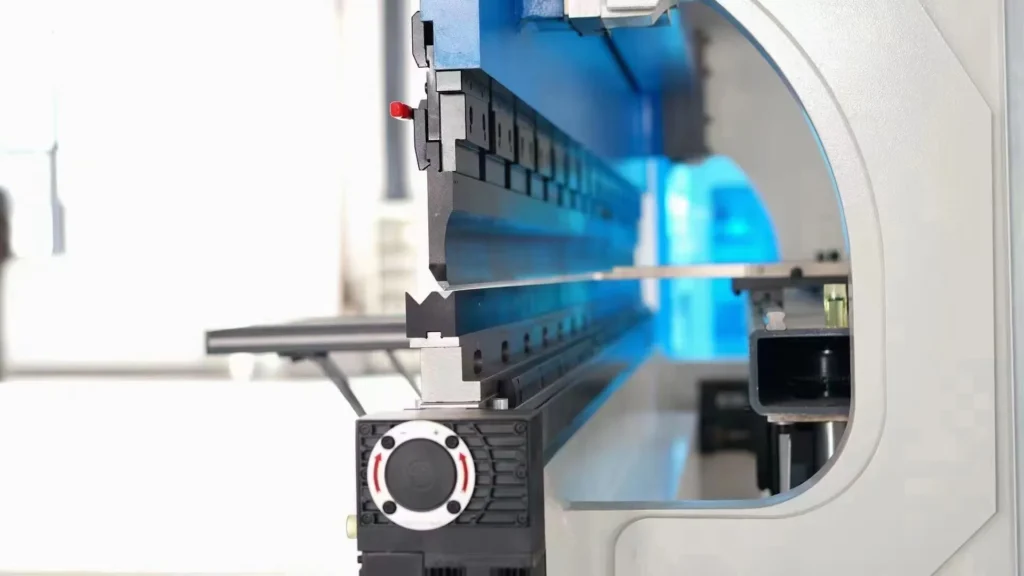

Tooling Clamping System

CUSTOMIZED SOLUTIONS TO INCREASE YOUR PRESS BRAKE PRODUCTIVITY

The fast clamping system can satisfy any needs, and therefore it represents the best choice for users that frequently change punches on their press brake machine and improve productivity.

Manual Upper Tool Clamping:

GLDMA CNC press brake use all Raw material is provided by qualified suppliers and chemical composition corresponds to international standards.Therefore, raw material yield and tensile strength are guaranteed.are standardized with a 8.4 x 3.5 mm safety groove, which keeps the tool from falling out.

Advantage:

- Safe and fast tool change

- Can be used without modifying Europe type punches

- Front clamp - vertical tool change

- Rear clamp - horizontal tool change

Wilson Pneumatic Clamping

This innovative fast clamping system can satisfy any needs,the Express Air clamping reduces press brake setup time and therefore it represents the best choice for users that frequently change punches on their press brakes for sale.

Advantage:

- Fast vertical tool change for all Europe type punches

- Safe and fast tool change

- Substantial improvement in time consumption and related costs

- Secure against tool falling down

- Available in manual, pneumatic and hydraulic models

- Easy to mount on your press brake.

Wila Hydraulic Clamping System:

The Wila’s ‘New Standard’ Tooling System has become market leader for precision, quality and flexibility for the GLDMA hydraulic press brakes for sale, the WILA’s state-of-the-art clamp system

Advantage:

- Long service life :>10 years

- Quick clamping for WILA style tooling

- Simple push-button loading

- Fast and safe tool changes:Reduce 80% time

- High-precision bending angle and flange edge