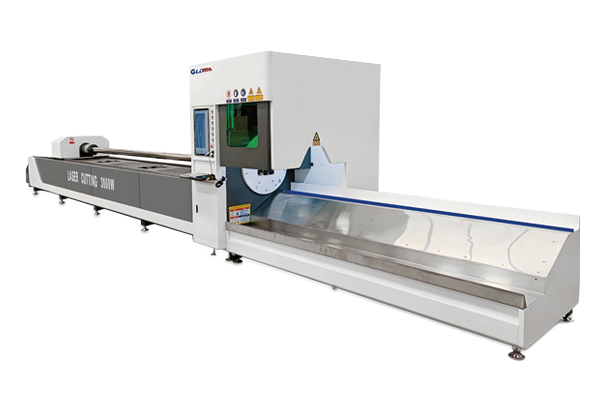

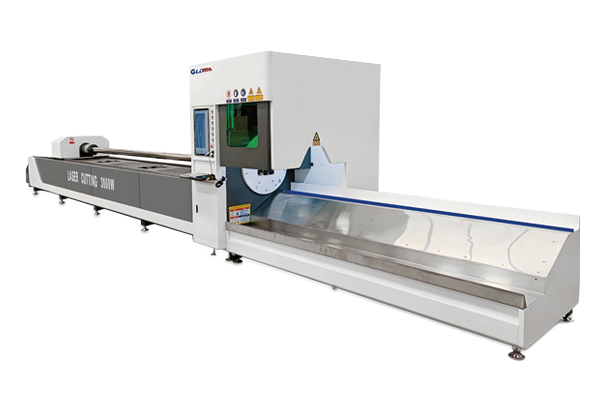

Tube Fiber Laser Cutting Machine

GLDMA Flatbed Tube Fiber Laser Cutting Machine 1000W-6000W.

Introducing a new way to process Laser Cutting on tubes with RAS-6000. The system is a unique combination of gldma Group’s proprietary Laser Technology and a robust mechanical structure designed by in-house R&D team. We re-imagined the whole conventional tube cutting process and developed RAS-6000, providing a complete solution to the complex industrial needs. This dedicated Laser Tube Cutting Machine is to provide extreme precision, productivity, and quality. With a dedicated Laser Pipe / Tube Cutting system, the company aims to achieve superior results for the tube processing industry.

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery Various working size optional

Auto Oil-filling

Intelligent system for auto oil filling oil cut-off avoided

Cost-Effective

Low waste of raw materisals Low investment with short payoff period

The Pipe Clamping Range is Wide

Integrated Machine Bed

Pneumatic roller support

Tubepro tube cutting software

Wide Processing Range, Can Cut a Variety of Tubes

Double Pneumatic Chucks, Ultra-short Tailing

Automatic Loading Equipment(Optional)

- Tubes are usually loaded to material laying area by transmission mechanism of which limiting device can make tubes in order.

- Tubes are clamped by 6 loading rollers that need no reset in a loading cycle, resulting in less waiting time and high cutting efficiency.

Application Materials of Tube Laser Cutter

Parameter of Laser Cutting Machine for Steel

| Model | RAS-6000 |

Pipe processing range(mm) | 6000* φ20~220 |

| (Square tube: 20*20~150*150) | |

| Laser Power(kw) | 1.5/2/3/4/6 |

| Maximum Speed(m/min) | 100 |

| Positioning Accuracy(mm) | ±0.05 |

| Repeated Positioning Accuracy(mm) | ±0.02 |

| Maximum Rotational Speed(r/min) | 100 |

| Maximum acceleration(G) | 0.8 |

| Table Maximum Load(KG) | 150 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |