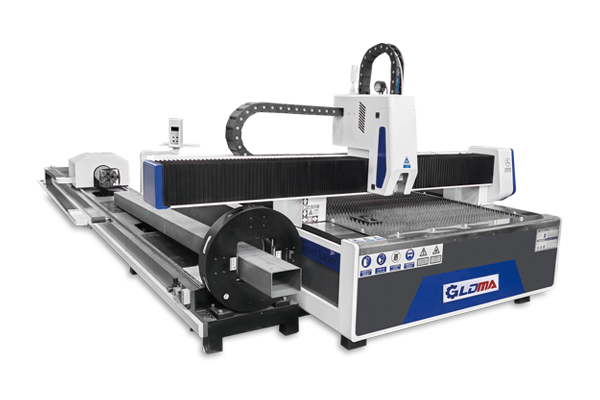

Tube&Plate Fiber Laser Cutting Machine

GLDMA Flate bed Tube Fiber Laser Cutting Machine 1000W-6000W.

RAS-B fiber laser cutting machine is specially designed for high-speed, high-quality cutting of various types of sheet metal and cutting of various cross-section metal pipes and profiles. This series of machines is specially designed for small and medium enterprises. Reliable components from the world’s leading companies, excellent design solutions and assembly quality make this model a sharp contrast with competitors manufacturers of similar equipment. The model can be equipped with a laser source with a power of 500 W to 6 KW(Raycus / IPG /Max/other brands).

High Precision Welding Bed

Integrated bed with sheet production line, self-sufficiency, shorter delivery Various working size optional

Auto Oil-filling

Intelligent system for auto oil filling oil cut-off avoided

Cost-Effective

Low waste of raw materisals Low investment with short payoff period

The Pipe Clamping Range is Wide

The pipe clamping range is wide,Round tube φ10-φ10, and Square tube side length is 10 * 10mm-220mm * 220mm. Support the cutting of various shapes of pipe materials, such as I-beam, channel steel, angle steel, elliptical pipe, waist pipe, multi-deformed pipe, etc.

Integrated Machine Bed

The unique industrial structure design gives it maximum stability and higher vibration resistance and damping quality. The compact spacing of 650mm ensures the agility of the chuck and the stability during high-speed driving.

Pneumatic roller support

Fixing the pipe effectively solves the deformation problem in the cutting operation of the long pipe.

Tubepro tube cutting and Plate Cutter software

RAS-B affordable metal tube laser cutter is equipped with FSCUT3000S pipe cutting system and FSCUT2000 Plate Cutting System, which suppors high-precision and high-efficiency cutting of square pipes, round pipes, racetrack-shaped and oval-shaped stretched pipes, as well as angle steel and channel steel.

Wide Processing Range, Can Cut a Variety of Tubes

It can process a wide range of tube sizes: round tube diameter ø15mm-ø220mm, square tube side length 15*15-150*150mm; With a 3D laser cutting head, it can easily cut H steel, I-beam, angle steel, channel steel and other profiles, as well as drop-shaped and concave shaped tubes.

Wide Processing Range, Can Cut a Variety of Tubes

It can process a wide range of tube sizes: round tube diameter ø15mm-ø220mm, square tube side length 15*15-150*150mm; With a 3D laser cutting head, it can easily cut H steel, I-beam, angle steel, channel steel and other profiles, as well as drop-shaped and concave shaped tubes.

Auto focusing laser head

Auto focusing laser head

The auto-focusing optical fiber cutting head has a built-in motor drive unit. The focus lens is driven by a linear mechanism to automatically change the position within the specified range. The continuous focus can be set by the program to complete the rapid perforation of thick plates and automatically cut plates of different thicknesses and materials.

Application Materials of Tube Laser Cutter

RAS-6000 laser pipe cutting machine can cut carbon steel, stainless steel, aluminum alloy, galvanized sheet, titanium alloy, manganese alloy, etc.It is widely used in metal tube processing, machinery manufacturing, auto parts manufacturing, electrical manufacturing,elevator manufacturing, petroleum machinery,food machinery, decorative advertisements, etc.

Parameter of Laser Cutting Machine for Steel

| Model | RAS-3015B/RAS-4015B/RAS-4020B/RAS-6015B/RAS-6020B Fiber Laser Cutting Machine |

| Working Area(mm) | 3050 * 1530/4050 * 1530 /4050*2030/ 6050* 1530/6050* 2030 |

| Laser Power(kw) | 1KW,1.5KW,2KW,3KW,4KW,6KW |

| Round Tube Processing Dim. | Φ20-Φ219mm |

| Square Tube Processing Dim. | 20*20mm-150*150mm |

| Max Single Tube Loading Weight | 100kg |

| Max Bundle Loading Weight | 1000kg |

| Chuck Rotating Speed | 90r/min |

| Max. Moving Speed | 90m/min |

| Max. Acc. Speed | 0.8G |

| Positioning Accuracy | ±0.05mm/m |

| Repositioning Accuracy | ±0.03mm |

| Maximum Speed(m/min) | 80 |

| X/Y Axis positioning accuracy(mm/m) | ±0.05 |

| X/Y Axis repeated positioning accuracy(mm) | ± 0.02 |

What is the Maximum Cutting Thickness?

| Material | 1KW | 1.5KW | 2KW | 3KW | 4KW | 6KW | 8kw | 12000W |

| Carbon Steel(mm) | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-20 | 0.4-25 | 0.4-25 | 0.4-25 | 0.4-45 |

| Stainless Steel(mm) | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-12 | 0.4-20 | 0.4-28 | 0.4-40 |

| Aluminum (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-8 | 0.4-12 | 0.4-16 | 0.4-18 | 0.4-22 |

| Brass (mm) | 0.4-3 | 0.4-5 | 0.4-6 | 0.4-6 | 0.4-8 | 0.4-14 | 0.4-16 | 0.4-20 |