Discover our technologies and find the product suited for your business

GLDMA Fiber Laser Cutting Machine

GLDMA Based on machinery design technology optimized through strict structural analysis, GLDMA has been manufacturing ultralight and high-precision industrial high-energy laser cutting machines.

What’s is Fiber Laser Cutter?

The Fiber laser cutting machine is to focus the laser emitted from the laser into a high power density laser beam through the optical path system. The laser beam is irradiated on the surface of the workpiece, making the workpiece reach the melting point or boiling point, while the high-pressure gas coaxial with the beam blows the molten or vaporized metal away.With the movement of the relative position of the beam and the workpiece, the material is finally formed into a slit, so as to achieve the purpose of cutting.

Fiber Laser cutting process replaces the traditional mechanical knife with invisible beam. It has the characteristics of high precision, fast cutting, not limited to cutting pattern, automatic typesetting to save materials, smooth incision, low processing cost, etc. It will be gradually improved or replaced in Traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece, and will not scratch the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing; the cutting heat-affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); the incision has no mechanical stress and no shearing burrs; high machining accuracy, good repeatability, and no damage to the surface of the material; CNC programming, can process any plan, and can cut the entire board with a large format without the need for Open the mold, economical and time-saving.

High Configuration Series Fiber Laser Cutting Machine

GLDMA top rated fiber laser cutting machine is designed for metal fabrication, including steel, aluminum, titanium, alloy, brass, copper, iron with different laser powers(1000W,1500W,2000W,3000W,4000W,6000W,8000W,12000W,2000W). Now the affordable fiber laser cutter for sale at a low price, with the best fiber laser cutting system service and support.

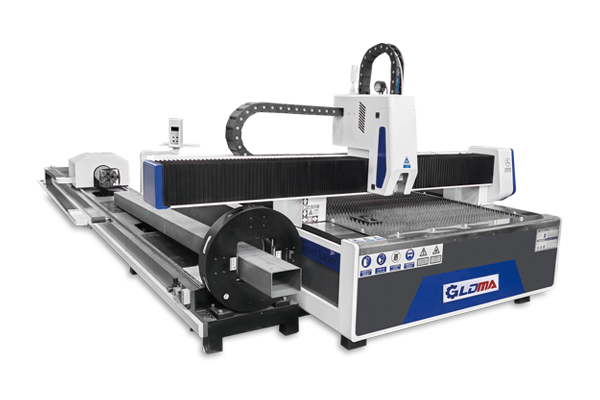

Tube and Plate Fiber Laser Cutting Machine

Full-Protective Double Exchange Platform laser cutting machine

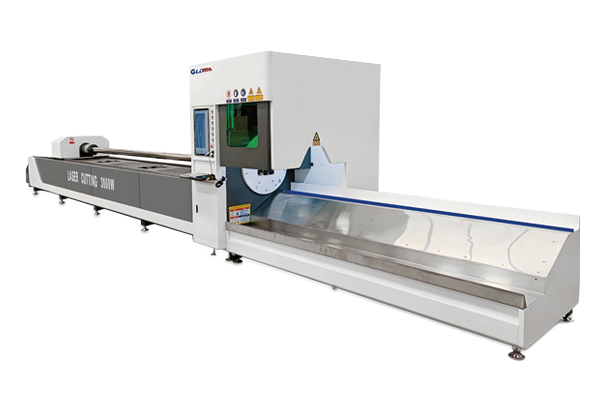

Tube Fiber Laser Cutting Machine

Handheld Fiber Laser Welding Machine

Fiber Laser Cutting Machine &Tube Laser Cutting Machine & Laser welding Machie

Customer case

1.Sheet Metal Fiber Laser Cutting Machine

The optical fiber laser cutting machine is a laser cutting machine using a fiber laser generator as a light source. And CNC sheet metal cutting machine is a newly developed new fiber laser, which can output a high energy density laser beam gathered on the surface of the workpiece, melting and gasifying the area irradiated by the ultra-fine focus spectrum, moving spot illumination through the CNC mechanical system to achieve perfect automatic cutting with high speed and precision.

Selecting sheet metal laser cutting machines for sale, first, you need to confirm the thickness and size of the cutting plate or pipe. GLDMA Fiber laser has the 1000 watt fiber laser cutting machine, 1500w fiber laser machine, fiber laser 2000w cutting machine, fiber laser 3000w cutting machine, 4kw fiber laser cutting machine, 6000w laser cutting machine, 10kw fiber laser cutting machine, 12kw laser cutter, 20000w fiber laser cutting, and more for you to choose from.

As fiber laser cutting machines continue to go deep into the market, more and more high-power metal cutting machine for sale. What is the limit wattage of the CNC metal sheet cutting machine? Although a 3kw laser cutting machine meets the needs of most users, it is not the limit!

In addition to the 3kw fiber laser cutting machine, there are also ultra-high power fiber laser cutting machines, including the 4kw fiber laser cutting machine, 6000w fiber laser cutting machine, and even 8000 watt, 10,000 watt, 12,000 watt, and 15,000 watt for high speed cutting speed and excellent workpiece processing quality. The thick plate cutting capacity increases with the fusion fiber laser and CO2 laser extension, and the thin plate cutting speed significantly improves.

2.Tube Laser Cutting Machine

Compared with the traditional cutting process, laser cutting flexibility is good – no need to open mold, greatly saving new product development time, cutting speed, and high precision. And the tube fibre laser cutting machine can achieve opening, cutting, cross-line and conventional ways difficult to achieve a variety of different complex graphics precision cutting.

Cutting speed is crucial, but the actual speed of the tubes laser cutting machine is relative. It’s more about the time the laser cutting machine for tubes takes to process a tube to meet specifications than the actual cutting speed on the tube. Steel tube cutting laser machines from GLDMA laser is self-developed to enable high-speed, high-quality laser cutting of profiles such as circular tubes, rectangular tubes, and special-shaped tubes. The new metal pipe laser processing line with tube laser cutting machine China not only achieves fully automatic production but also breaks through the limitations of plane cutting, achieving multi-dimensional cutting. In a word, the fiber laser steel tube cutting machine is the metal pipe laser cutting choice!

The metal pipe cutting machine has variable power to cut various materials through light depending on the end product. The tube cutting laser machine is widely used in fitness equipment, construction machinery, home manufacturing, and other industries. Under the different applications of various shapes of pipe, the cutting technology of metal pipe is put forward higher requirement.

On the other hand, the CNC laser tube cutting machine is free of preventive maintenance. All you need to do is conduct a regular check and replace the air filter routinely. GLDMA is a well-known tube laser cutting machine brand worldwide, offering various high-quality fiber laser processing machines to suit customers’ needs. Our square tube laser cutting machines provide an excellent solution for laser cutting of a wide variety of tubular profiles and sections of various materials. Moreover, GLDMA laser cutting also provides tube laser cutting machine and a related instruction manual for each client to select the product more easily.

In the past, the fiber laser aluminum cutting could be used to cut thin materials. With the development of the cutting technology, fiber laser processing machines can use the narrower beam to process thin materials, which allows for faster processing of different-sized materials on the same fiber laser cutting machine. GLDMA laser is one of China’s leading CNC fiber laser cutting machine manufacturers.

3.Laser Welding Machine

With the emergence of the latest laser technology, laser machine welding technology has become popular. The welding machine laser is a precise and efficient welding method that uses a high-energy-density laser beam as a heat source to allow metal parts to be assembled. Industrial laser welding machines can effectively combine the molecular layers of the weld and realize the seamless joint of the weld.

The laser welding small machine adopts optical fiber to transmit high energy density beams. The laser beam is emitted through the handheld welding head of the laser beam welding machine to weld stainless steel, aluminum alloy, etc. The hand held fiber laser welding machine is flexible and convenient to operate. Contact us today to get the best manual laser welding machine price!

Unlike the other traditional welding processes, the CNC laser welding machine can accomplish the job in much lesser time. The metal laser welding machine is equipped with a single-mode continuous fiber laser and provides high beam quality. The laser metal welding machine adopts the modular and water-cooling way, with the system highly integrated and continuously adjustable laser power. The ss laser welding machine is free from maintenance and highly reliable.

The speed of the welding process, the high level of automation, and the ability to control the welding quality during the operation make laser machine welding a widely used method in many industrial sectors such as the medical industry, electronics, toolmaking, and the automotive sector. Find the best stainless steel spot laser welding machine and aluminium laser welding machine at the best laser welding machine price in the leading aluminium laser welding machine in China – GLDMA

With the emergence of the latest laser technology, laser machine welding technology has become popular. The welding machine laser is a precise and efficient welding method that uses a high-energy-density laser beam as a heat source to allow metal parts to be assembled. Industrial laser welding machines can effectively combine the molecular layers of the weld and realize the seamless joint of the weld.

The laser welding small machine adopts optical fiber to transmit high energy density beams. The laser beam is emitted through the handheld welding head of the laser beam welding machine to weld stainless steel, aluminum alloy, etc. The hand held fiber laser welding machine is flexible and convenient to operate. Contact us today to get the best manual laser welding machine price!

Unlike the other traditional welding processes, the CNC laser welding machine can accomplish the job in much lesser time. The metal laser welding machine is equipped with a single-mode continuous fiber laser and provides high beam quality. The laser metal welding machine adopts the modular and water-cooling way, with the system highly integrated and continuously adjustable laser power. The ss laser welding machine is free from maintenance and highly reliable.

The speed of the welding process, the high level of automation, and the ability to control the welding quality during the operation make laser machine welding a widely used method in many industrial sectors such as the medical industry, electronics, toolmaking, and the automotive sector. Find the best stainless steel spot laser welding machine and aluminium laser welding machine at the best laser welding machine price in the leading aluminium laser welding machine in China – GLDMA.

The hand held fiber laser welding machine integrates the fiber laser, handheld welding head, laser control system, safe beam emission system, and cooling system. The hand laser welding machine is compact, beautiful, and easy to move to allow the customer to be not confined by space when selecting the location and scope of work. Hymson offers small laser welding machine and laser welding machine for sale, such as 2000w laser welding machine, laser welding machine for stainless steel, steel laser welding machine, laser welding machine for aluminum, fiber laser welding machine, etc.

GLDMA laser is a professional laser welding machine supplier in China, and we offer excellent laser beam quality with the newest technology and high-speed laser welding machine China. Moreover, we offer the fiber laser welding machine for sale at the best fiber laser welding machine price for production welding. Our laser welding machines feature low-cost, high-quality, fast response, rich selection, one-stop solutions, etc..

The hand held fiber laser welding machine integrates the fiber laser, handheld welding head, laser control system, safe beam emission system, and cooling system. The hand laser welding machine is compact, beautiful, and easy to move to allow the customer to be not confined by space when selecting the location and scope of work. GLDMA offers small laser welding machine and laser welding machine for sale, such as 1500w laser welding machine.

In addition to sheet metal laser cutting machines, GLDMA Laser also offers the laser cutting sheet metal machine, sheet metal cutting machine, tube fiber laser cutting machine, industrial laser welding machine, aluminum laser cutting machine, Hydraulic Shearing Machine,V Grooving Machine,CNC Press Brake,Plate Rolling Machine,Plasma cutting machine,Ironworker Machine, and so on. The best laser sheet metal cutting machine price can be found in GLDMA CNC laser cutting machine factory!